From the Desk of Andrew Macdonald, PAC NEXT Project Manager:

Envisioning Reuse/Refill at Scale: a framework to assess viability

For over fifty years, waste management hierarchies have shown reuse as a higher order approach, second only to reduction. This holds true in current, well thought-out frameworks such as SPRING’s Packaging Sustainability Roadmap and the Ellen MacArthur Foundation’s (EMF) Upstream Packaging Guide. Despite this, the recent EMF Global Commitment Report notes an alarming lack of investment in alternatives to single-use packaging, with signatories reporting about 2% of plastic packaging as reusable – where EMF says at least 20% is viable for conversion to reuse. Perhaps recent Coca-Cola and Starbucks announcements are harbingers of change to come.

Moving from ‘2 to 20’ will not be easy. High on the list of single-use packaging’s powers of incumbency is its gold-standard convenience, hard-wired to recycling/garbage bins. A global preoccupation with improved recycling seems to have limited our collective capacity to envision, and implement, viable reuse/refill solutions. We need more of what Upstream’s Miriam Gordon calls ‘cross-pollination’ – bringing a vision of what successful reuse systems look like to local communities, businesses and legislators.

Main image – © A. Macdonald/PAC Global; Top Right Image: https://plastics.ellenmacarthurfoundation.org/upstream#resources

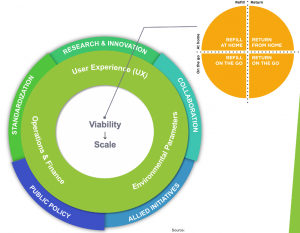

To contribute to this vision-building I’ve sketched a framework, which I hope can help reuse ecosystem actors think about, and visualize, the viability of models. I see the framework as the ‘how’ aspect of reuse moving to scale, layered onto EMF’s reuse types, which I wrote about previously, that help understand the ‘what.’ All feedback is welcome, and greatly appreciated.

To achieve initial viability any model must address three parts (UX, Ops/Finance, Env. Parameters). These core parts interconnect with other areas that have potential to accelerate progress toward widespread adoption/scale. The core is a three-legged stool: Without top notch User Experience (UX) the whole idea fails or remains niche. Without well-oiled ‘back-of-house’ operations, the UX is undermined –and a business case is, of course, essential. Without due diligence on environmental impacts, the model risks being counter-productive. Here’s a brief explanation of the framework:

User Experience (UX)

The UX has a lot going on, I suggest thinking of it in two ways. As does Closed Loop Partners, in this excellent report, think of it as a journey with key stops, such as: awareness, sign-up, point of sale, product experience, packaging look/feel, return/refill. Second, consider key requirements that cross-cut the journey. For example, reuse/refill systems must aim to match the convenience of single-use. Other requirements are health and safety, accessibility, affordability and in many cases, a digital interface. As a judge for the recent PAC Global Awards, I was not alone in my appreciation for the rigorous attention to UX detail demonstrated by best-in-show winner Tim Hortons.

With respect to convenience, viable reuse pathways must address consumer behaviour change. This is underscored in recent, important multi-disciplinary work which combines behavioural science with Life Cycle Assessment (LCA). Of note is a partnership between WRAP, Asda and Unilever to collect data from refillable product trials, and develop ideas for making refill more accessible and attractive to shoppers. Affordability is especially important for widespread adoption: Algramo’s recognition of a packaging related poverty tax, and Asda’s price promise are examples of efforts to address this requirement.

Worth noting too, that in ‘on-the go’ models, retailers play a multi-faceted role, both as user and delivery agent. As a user, benefits may include lower packaging cost and waste; as a delivery agent, retailers play a key role in customer-facing activities like employee training, which can make or break a model. When a refill-on-the-go customer asks, “How does this scale work?”, the answer must be “Let me help you.”

Operations & Finance

Plugging into the UX is a set of things, called ‘reverse logistics’ or ‘logistics’ – I like the ‘operations’ umbrella. It starts with packaging design, sourcing and manufacturing. Once the packaging is ‘in-market’ a back-of-house operations journey shadows the UX journey, where key stops are threaded together with transportation. Return/refill journeys vary, but include collection or dispensing units; storage capacity; washing/sanitizing/inspecting; prefill/fill, and redistribution.

Tim Hortons return-on-the-go pilot in Canada

Cross-cutting requirements are logistics optimization, and IoT enabled track-and-trace capability. The latter is valuable for inventory management, quality control, and evaluation of key metrics like ‘actual reuses.’ Actors offering operations services include: conventional players in logistics/delivery (Canada Post, FedEx etc.); washing/sanitization specialists like Ecolab, Dishcraft, Uzaje; and those licensing tracking software, like Reusables. Interesting too is the emergence of companies like RE, that offer B2B expertise to prospective and/or existing reuse providers. For B2B containers, IFCO and Tosca are major providers, and the Reusable Packaging Association, and its new podcast, is an excellent resource.

Cross-cutting these operations is the business case. For example, Tesco’s Head of Packaging James Bull said this about their Loop pilot, “We’ve sold more than twenty thousand items already, but a lot of work is needed before it’s ready to scale. It currently costs more to sell food in this way, and we know customers are reluctant to pay a premium for reusable packaging. As a result, we’re fine-tuning and developing our proposition to find ways for it to operate efficiently and perform at scale.”

More work needs to be done/shared in this area, but, for example, this Upstream report provides a compelling business case for reuse conversion in dine-in settings. Another aspect is financial investment, which appears to be have momentum: examples include Closed Loop Partner’s investment in Algramo, ClubZero’s oversubscribed crowdfunded campaign, and raises by Uzaje (industrial washing) and Returnity (e-comm delivery).

Algramo’s Qyos cashless, touchless refill-on-the-go system in Jakarta. Source: https://enviu.org/work/qyos-by-algramo/

Environmental Parameters

There is no point investing in a reuse/refill model if, despite best intentions, it fails to reduce negative environmental impacts when compared with a single-use alternative(s). This Zero Waste Europe report, which reviews LCA findings, identifies key environmental parameters. A parameter is a ‘measurable factor that forms part of a system’ – very useful for the due diligence piece. As with UX and Operations/Finance, this part has a lot of depth. A few highlights:

Look hard enough, and you’ll find a report, or a headline, that confirms a bias. Approach due diligence based on sound science, work from credible packaging sustainability frameworks (as noted above), and seek trusted advice – like that offered by PAC Global!

The environmental parameters mirror the operations journey. Generally, with single-use packaging the vast majority of environmental impacts are ‘upstream’ – material extraction and packaging manufacturing. With reuse, the upstream impacts are amortized over many uses – so the impact ‘hot-spots’ are those that reoccur with each cycle, such as transportation and washing.

Various tools can help assess parameters, and establish a ‘break-even point’: the point at which the environmental impacts of a reusable packaging option are estimated to be equal to those of a single-use option employed for the same purpose. Tools include full and streamlined Life Cycle Assessment (LCA), and others, such as: UP Scorecard, PAC Global’s PIP360, KIDV Calculation Tool.

Regarding parameters, transportation alone is complex – influenced by distance, mode, and route optimization. Other parameters include: return rates, washing/sanitizing, material selection (weight) and functionality (nest/fold), sourcing (recycled and/or biobased content), and end-of-life treatment. Of note is material engineering innovation allowing reusable containers to match the weight of single-use, while maintaining or improving functionality (e.g., Bockatech). This type of innovation is at play in the Starbucks Europe trials.

My view is that a growing body of relevant research is gradually allowing for sound ‘proxy’ decisions on environmental viability, especially in particular market segments. Some due diligence is always required, but for example, for food takeout containers the weight of evidence shows reuse models as environmentally preferred.

I hope this piece helps highlight the core aspects of reuse/refill viability. Stay tuned for Part 3, where I’ll shed light on the other aspects of the framework: Standardization, Collaboration, Public Policy, Research and Innovation, and Allied Movements. And please join me, and expert guests, at our Reusable Packaging Mini-Course, March 24th, 2022.